Best Practices for Installing Earthing Switches in Switchgear

Industry Background and Market Demand

Earthing switches are critical components in medium- and high-voltage switchgear, ensuring safe maintenance and operational reliability. As power distribution networks expand globally, the demand for robust earthing solutions has grown, driven by stricter safety regulations and the need for grid stability. Industries such as utilities, manufacturing, and renewable energy rely on properly installed earthing switches to mitigate electrical hazards during maintenance or fault conditions.

The market increasingly prioritizes modular, maintenance-friendly designs that comply with IEC and IEEE standards. With the rise of smart grids and digital substations, earthing switches must also integrate seamlessly with monitoring systems, reinforcing the importance of correct installation practices.

Core Concepts and Key Technologies

An earthing switch is a mechanical switching device that creates a safe discharge path for residual currents in de-energized circuits. Unlike disconnectors, earthing switches are not designed to interrupt load currents but to ensure equipment is grounded before servicing.

Key technologies include:

- High-Short-Circuit Withstand Capability: Ensures the switch can handle fault currents without damage.

- Fast-Closing Mechanisms: Minimizes arcing risks during operation.

- Interlocking Systems: Prevents accidental operation when the circuit is live.

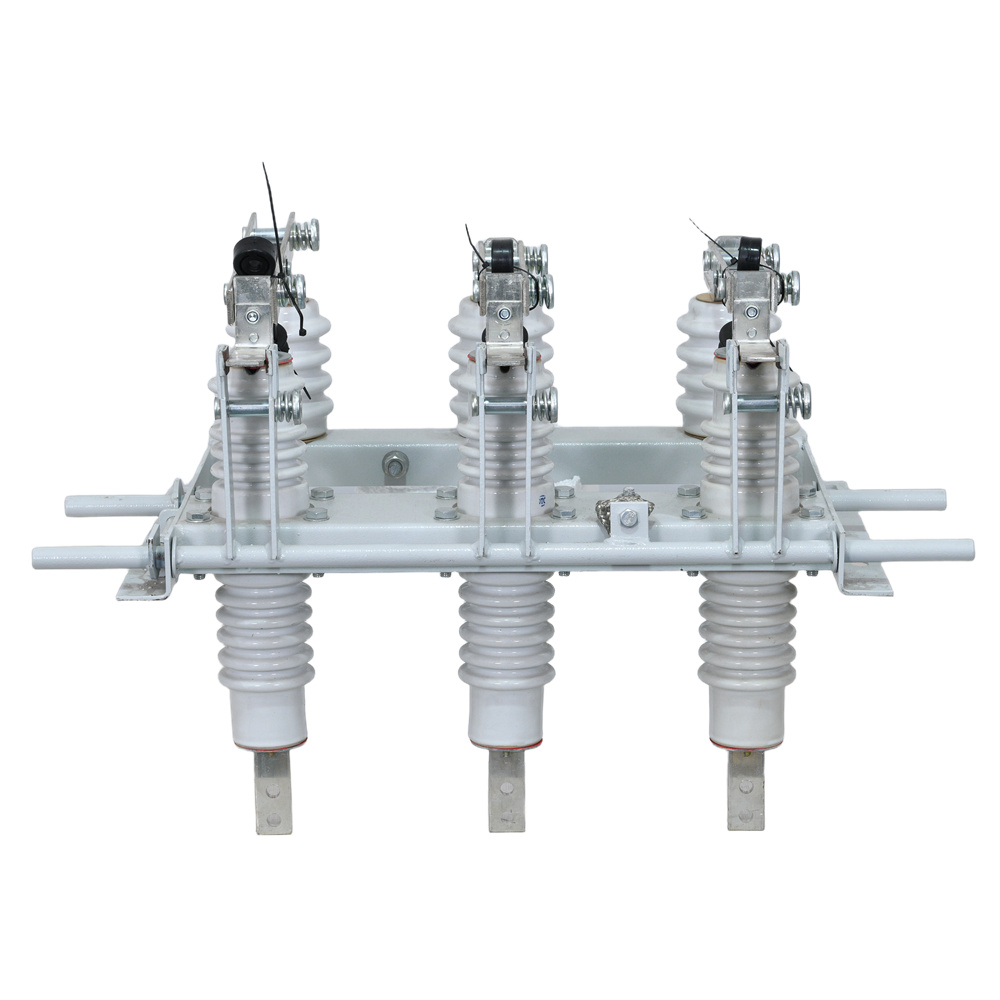

Product Structure, Materials, and Manufacturing

Earthing switches consist of:

- Contacts: Typically made of copper or silver-plated alloys for low resistance and corrosion resistance.

- Operating Mechanism: Spring-loaded or motor-driven for rapid, reliable switching.

- Insulating Components: Epoxy resin or porcelain insulators to withstand high voltages.

Manufacturing processes emphasize precision machining to ensure tight tolerances, while rigorous testing (e.g., dielectric, mechanical endurance) validates performance under extreme conditions.

Critical Factors Affecting Quality and Performance

1. Contact Resistance: Poor contact surfaces increase resistance, leading to overheating.

2. Mechanical Durability: Frequent operations demand robust hinges and linkages.

3. Environmental Resistance: Switches in coastal or industrial areas require enhanced corrosion protection.

4. Interlocking Compliance: Non-compliance risks unsafe operation.

Supplier Selection and Supply Chain Considerations

When sourcing earthing switches, evaluate suppliers based on:

- Certifications: Compliance with IEC 62271 or ANSI/IEEE standards.

- Testing Protocols: Evidence of type and routine testing.

- Lead Times and Customization: Ability to meet project-specific requirements.

- After-Sales Support: Availability of spare parts and technical assistance.

Reputable manufacturers often provide detailed documentation, including installation guides and maintenance manuals, ensuring long-term reliability.

Common Challenges and Industry Pain Points

1. Misalignment During Installation: Improper alignment increases mechanical stress, reducing lifespan.

2. Inadequate Maintenance: Dust accumulation or oxidation degrades contact performance.

3. Compatibility Issues: Mismatched switchgear ratings can lead to unsafe conditions.

4. Regulatory Non-Compliance: Failure to meet local grid codes may result in penalties.

Application Scenarios and Case Studies

Utility Substations

A European utility upgraded its 132 kV switchgear with fast-acting earthing switches, reducing maintenance downtime by 30% and improving worker safety.

Renewable Energy Plants

A solar farm in the U.S. integrated earthing switches with remote monitoring, enabling real-time status checks and predictive maintenance.

Industrial Facilities

A steel plant in Germany implemented corrosion-resistant earthing switches, extending service intervals despite harsh environmental conditions.

Current Trends and Future Developments

1. Smart Earthing Switches: IoT-enabled sensors for condition monitoring.

2. Modular Designs: Easier retrofitting in aging infrastructure.

3. Eco-Friendly Materials: Reduced SF6 usage in gas-insulated variants.

4. Automated Testing: AI-assisted diagnostics for predictive maintenance.

FAQ

Q: Can earthing switches be retrofitted into older switchgear?

A: Yes, but compatibility checks (voltage rating, mechanical fit) are essential.

Q: How often should earthing switches be inspected?

A: Annual inspections are recommended, with more frequent checks in high-usage environments.

Q: What is the typical lifespan of an earthing switch?

A: Well-maintained switches last 20–30 years, depending on operational conditions.

Conclusion

Proper installation of earthing switches in switchgear ensures operational safety and compliance with industry standards. By focusing on material quality, mechanical precision, and supplier reliability, engineers can optimize performance while addressing common challenges. As technology evolves, smart and sustainable solutions will further enhance the role of earthing switches in modern power systems.

الهاتف: +8613736779975

البريد الإلكتروني: sales@vcbbreaker.com

المياه: طريق 66، منطقة التنمية الاقتصادية المميزة، زيجي، الصين

حقوق الطبع والنشر © 2025 Eberry Electric Group جميع الحقوق محفوظة

يستخدم هذا الموقع ملفات تعريف الارتباط لضمان حصولك على أفضل تجربة على موقعنا.

تعليق

(0)